Introduction

Did you know that black masterbatch plays a crucial role in enhancing the functionality of plastic materials? This concentrated mixture of carbon black, carrier resin, and additives is vital in numerous industries.

In this article, we’ll explore what black masterbatch is and how high grade black masterbatch stands out for its superior color quality, UV resistance, and mechanical strength. You'll learn how it’s made, its various applications, and why it remains an essential component in modern manufacturing.

What is Black Masterbatch?

Defining Black Masterbatch

Black masterbatch is a concentrated mixture of carbon black, a carrier resin (such as polyethylene or polypropylene), and various additives. These components are combined to impart a rich black color to plastics while improving their mechanical, electrical, and UV-resistant properties. Masterbatches are commonly used in industries like packaging, automotive, and construction, providing both aesthetic appeal and practical benefits.

Key Components of Black Masterbatch

Black masterbatch is made up of three main components, each contributing to its functionality and performance. These components are carefully selected to ensure the masterbatch provides optimal results in various applications.

Component | Description |

Carbon Black | The primary ingredient that imparts deep black color to plastics and absorbs UV radiation, providing environmental protection. |

Carrier Resin | Polymers like polyethylene (PE) or polypropylene (PP) that help disperse carbon black evenly for uniform coloring and enhanced performance. |

Additives | Stabilizers, antioxidants, and processing aids that improve plastic strength, flexibility, and heat resistance. |

How Black Masterbatch Improves Plastic Properties

Black masterbatch doesn't just provide color; it also improves several essential properties of plastics:

● UV Protection: Carbon black absorbs UV rays, preventing degradation and extending the lifespan of outdoor plastic products.

● Mechanical Strength: It enhances the strength and durability of plastic products, making them more resistant to wear and tear.

● Thermal Stability: By stabilizing the thermal properties of plastics, black masterbatch ensures that products can withstand higher temperatures without losing their integrity.

What Makes High Grade Black Masterbatch Different?

Superior Pigment Quality

High-grade black masterbatch contains carefully selected, high-quality carbon black, ensuring consistent color intensity and opacity. The superior pigment quality results in a deeper, richer black color that enhances the appearance of plastic products, making them more attractive for consumer goods and industrial applications.

Enhanced UV Protection and Durability

One of the most significant benefits of high grade black masterbatch is its exceptional UV protection. The high-quality carbon black used in premium masterbatches absorbs more UV radiation, providing plastic products with extended durability and resistance to sunlight-induced degradation. This makes it an ideal choice for outdoor applications, such as automotive parts and agricultural films.

Precision in Application and Processing

High-grade black masterbatch offers excellent dispersion and uniformity during processing. The carrier resin ensures that the carbon black and additives are evenly distributed throughout the plastic, preventing streaks or uneven coloring. This precision results in more consistent and aesthetically pleasing final products. It also makes the manufacturing process smoother, reducing the risk of defects and enhancing production efficiency.

Feature | Benefit |

Superior Pigment Quality | Deeper, richer black color for aesthetics |

Enhanced UV Protection | Longer-lasting durability and resistance |

Precision in Application | Uniform dispersion for consistent results |

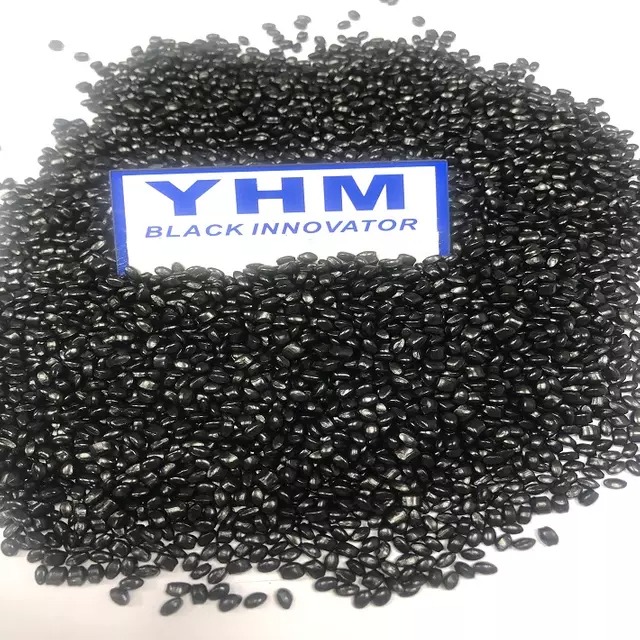

![high grade black masterbatch high grade black masterbatch]()

The Manufacturing Process of Black Masterbatch

1.Ingredient Selection

The production of high-quality black masterbatch begins with the careful selection of carbon black and carrier resins. Carbon black grades vary in terms of their jetness (blackness), particle size, and UV absorption capabilities. Manufacturers select the appropriate grade based on the specific performance requirements of the final product, such as UV resistance, color intensity, or conductivity.

2.Extrusion and Pelletization

The selected ingredients are mixed and fed into an extruder, where they are heated and blended together. The extrusion process ensures that the carbon black is evenly dispersed in the carrier resin. Once mixed, the molten material is cooled and cut into pellets. These pellets are then ready for use in plastic manufacturing processes like injection molding or sheet extrusion.

3.Quality Control

To ensure the highest quality, black masterbatch undergoes rigorous testing. Manufacturers assess color strength, dispersion, and consistency to ensure that the final product meets industry standards. Any deviations from the required specifications are corrected before the masterbatch is shipped for use in production.

Common Applications of Black Masterbatch

Packaging Industry

In packaging, black masterbatch is commonly used to produce films, bags, and containers. Its ability to provide UV protection helps extend the shelf life of products, making it ideal for packaging food, pharmaceuticals, and other goods that require protection from sunlight. The deep black color also enhances the visual appeal of packaging materials.

Automotive Industry

Black masterbatch plays a crucial role in the automotive industry, where it is used for both interior and exterior parts. It enhances the durability and appearance of components like bumpers, dashboards, and trims, while also providing UV resistance to prevent fading and degradation from prolonged sun exposure.

Agricultural Applications

In agriculture, black masterbatch is used in mulch films and greenhouse covers. It helps protect crops by controlling light exposure, maintaining soil temperature, and preventing weed growth. The UV resistance of black masterbatch also ensures that these films have a long-lasting performance under harsh outdoor conditions.

Household Appliances and Electronics

Black masterbatch is widely used in household appliances and electronic devices like TVs and vacuum cleaners. It not only gives these products an appealing finish but also contributes to their durability and thermal stability. In electronics, black masterbatch can also provide antistatic properties, reducing the risk of static charge buildup.

Industry | Application |

Packaging | Films, bags, and containers with UV protection and enhanced visual appeal. |

Automotive | Interior and exterior parts with improved durability and UV resistance. |

Agriculture | Mulch films and greenhouse covers that protect crops and control light. |

Household Appliances | Products like TVs and vacuum cleaners with enhanced durability and thermal stability. |

Advantages of Using High Grade Black Masterbatch

Cost-Efficiency in Production

High-grade black masterbatch offers a cost-effective solution for coloring plastics. By using concentrated pellets, manufacturers can achieve the desired color intensity with a minimal amount of material, reducing waste and lowering production costs. Additionally, the ease of processing and precise dosing controls further enhance the cost-efficiency of using masterbatch in manufacturing.

Superior Dispersion and Homogeneity

Unlike powdered pigments, black masterbatch ensures a uniform distribution of color and additives throughout the plastic, eliminating inconsistencies such as streaks or uneven coloring. The use of pellets also simplifies handling, reducing the potential for contamination and making the entire production process more efficient.

Improved Safety and Ease of Use

Since black masterbatch is encapsulated in a carrier resin, it eliminates the health risks associated with handling powdered pigments, which can be hazardous to workers. This makes it a safer choice in industrial environments. The easy-to-handle pellets also reduce the risk of contamination during manufacturing, ensuring higher-quality end products.

Versatility Across Various Plastics

Black masterbatch can be used with a wide range of plastic resins, including polyethylene (PE), polypropylene (PP), and polystyrene (PS). This versatility makes it suitable for various applications, from packaging to automotive parts, and allows manufacturers to achieve consistent results across different product lines.

Advantage | Description |

Cost-Efficiency in Production | Concentrated pellets reduce material use, waste, and overall production costs. |

Superior Dispersion and Homogeneity | Ensures uniform color distribution and eliminates inconsistencies. |

Improved Safety and Ease of Use | Encapsulated in carrier resin, reducing health risks and contamination. |

Versatility Across Various Plastics | Can be used with various resins (PE, PP, PS), making it suitable for diverse applications. |

![high grade black masterbatch high grade black masterbatch]()

Why High Grade Black Masterbatch Remains Essential in Modern Manufacturing

Evolution of Masterbatch Technology

Black masterbatch has come a long way since its early days. As manufacturing technology has evolved, so have the methods used to produce masterbatch. Today, high-quality masterbatch is engineered to meet the specific demands of modern industries, offering enhanced performance and better environmental compliance.

Environmental Considerations and Sustainability

Sustainability is a growing concern in the plastics industry. High-grade black masterbatch formulations are now being developed with eco-friendly carrier resins and recycled materials. This shift aligns with the increasing demand for sustainable solutions, allowing manufacturers to reduce their environmental impact while still achieving high performance in their products.

Factor | Description |

Evolution of Masterbatch Technology | Modern masterbatch is engineered for better performance and environmental compliance. |

Environmental Considerations and Sustainability | New formulations use eco-friendly resins and recycled materials, aligning with sustainability goals. |

Compared to traditional powder pigments, black masterbatch offers several advantages. It ensures superior dispersion, better homogeneity, and easier processing. Additionally, it reduces dust and health risks, making it a safer and more efficient solution for manufacturers. The precise control over color and additive dosage further enhances the quality of the final product.

Conclusion

Black masterbatch is a crucial component in the plastics industry, offering both aesthetic and functional benefits. High grade black masterbatch ensures superior color quality, UV protection, and mechanical strength, making it essential for industries like packaging, automotive, and agriculture. Its ease of use, cost-effectiveness, and versatility across different plastic resins make it a valuable solution for modern manufacturing. As the demand for sustainable, high-performance materials rises, companies like YHM Masterbatches Co., Ltd. are leading the way in providing durable, high-quality products to meet the needs of a competitive market.

FAQ

Q: What is black masterbatch for plastics?

A: Black masterbatch is a concentrated mixture of carbon black, carrier resin, and additives used to improve the color and properties of plastics. It enhances UV resistance, mechanical strength, and aesthetics in various plastic products.

Q: Why is high grade black masterbatch important?

A: High grade black masterbatch ensures superior color quality, UV protection, and mechanical strength, making it ideal for demanding applications like automotive and packaging industries.

Q: How does black masterbatch improve plastic properties?

A: Black masterbatch improves plastic by enhancing UV resistance, strength, and durability, while providing a rich, consistent black color. It is especially useful in high quality injection molding & sheet extrusion processes.

Q: What are the applications of high grade black masterbatch?

A: High grade black masterbatch is used in packaging, automotive parts, agricultural films, and household appliances, providing UV protection and durability.

Q: How cost-effective is black masterbatch?

A: Black masterbatch is cost-effective as it ensures uniform color and enhances the durability of plastic products with minimal material use, reducing production costs.

Q: Can black masterbatch be used with all plastic types?

A: Yes, black masterbatch is versatile and can be used with various plastic resins like PE, PP, and PS, making it suitable for multiple applications, including high quality injection molding & sheet extrusion.